Battery Systems

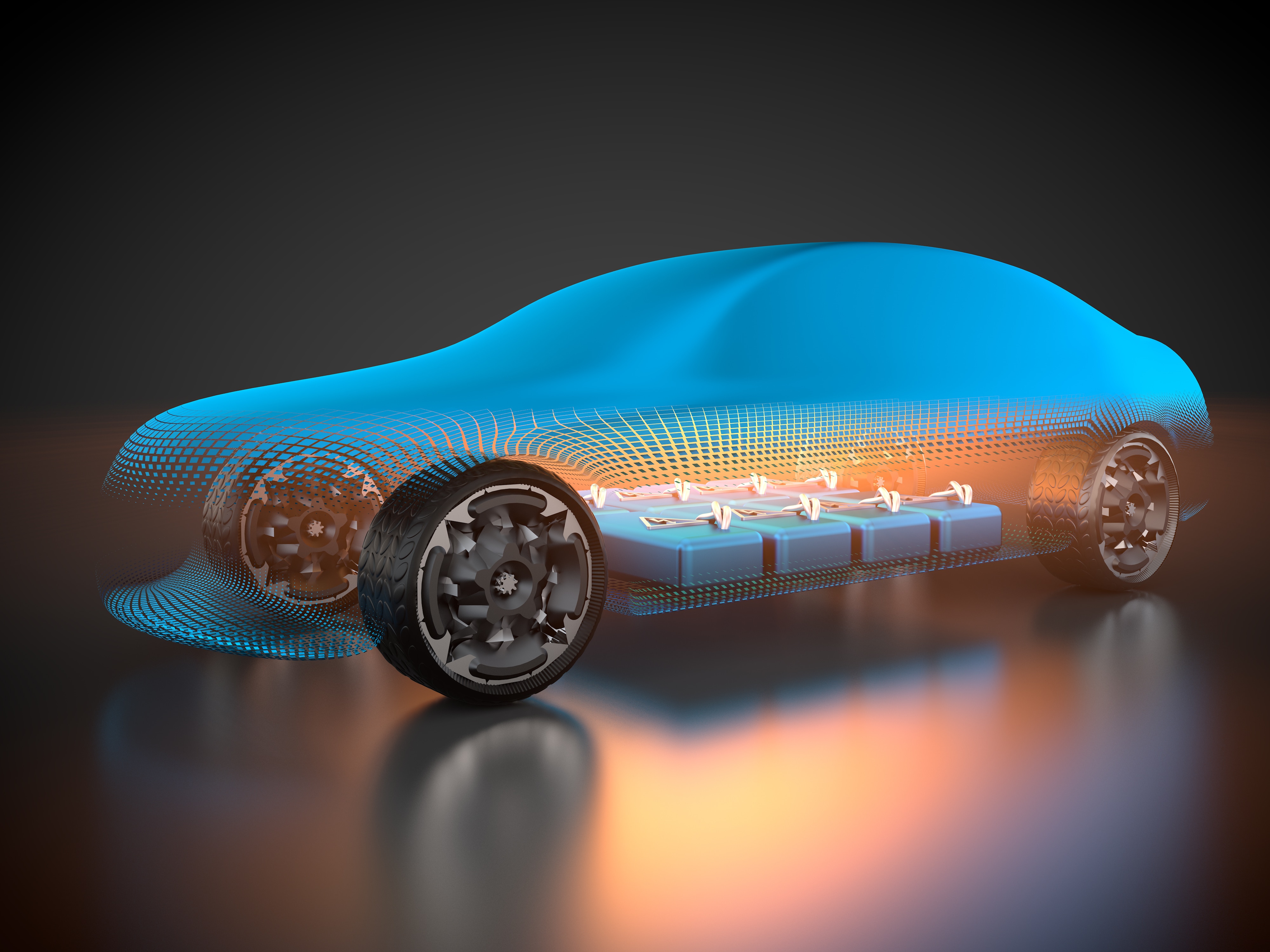

Transforming battery systems to help create a better EV

Find battery system solutions to design a better EV

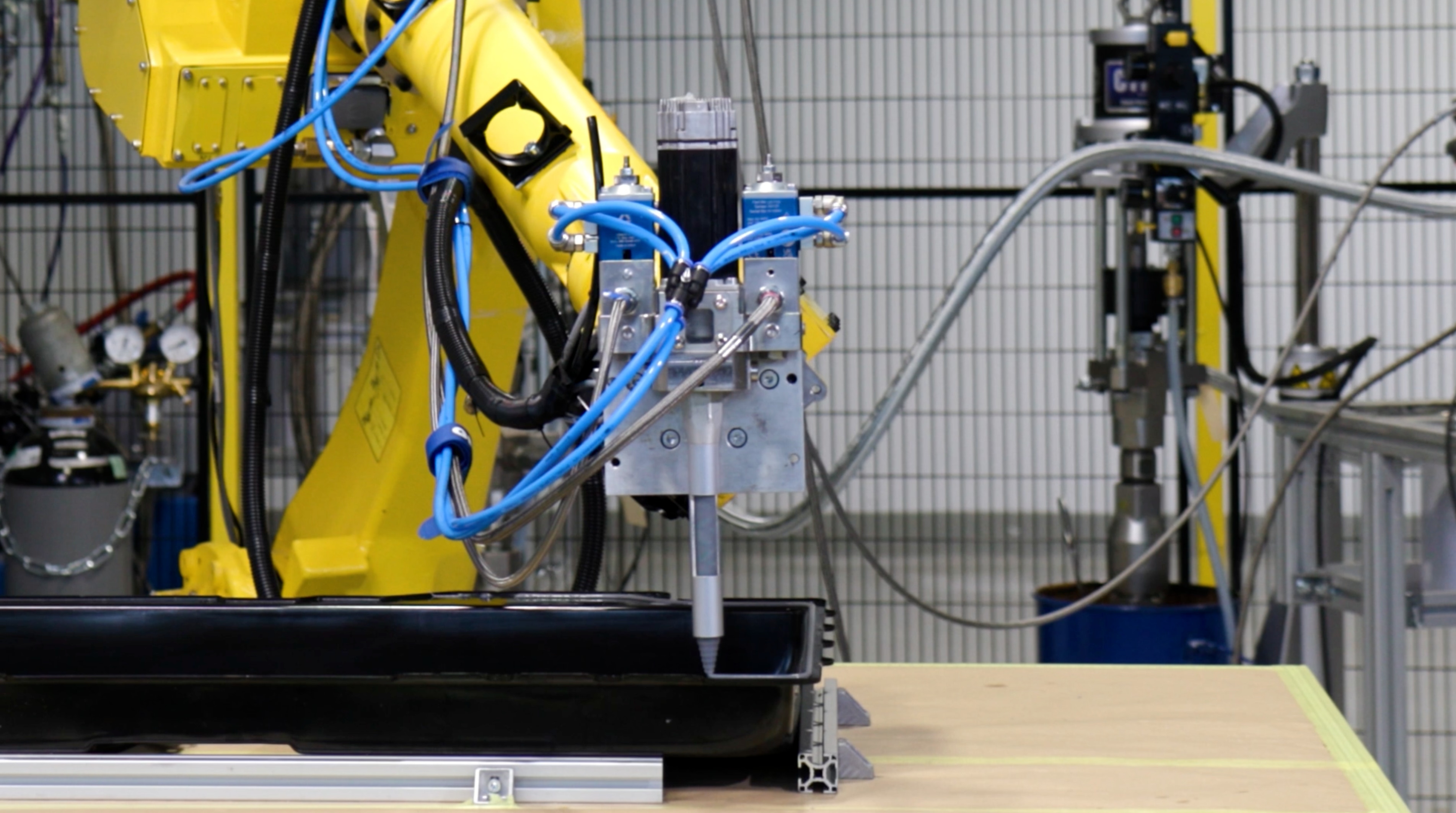

The growing EV market offers OEMs and suppliers the opportunity to lead battery development. Dow's innovative materials deliver lightweight, energy-dense battery packs that resist overheating and integrate seamlessly with automated assembly systems.

Explore our broad portfolio of battery system solutions to optimize your battery pack assembly and meet your battery fire protection (BFP) challenges.

Looking for battery pack design flexibility?

Our VORATRON™ and DOWSIL™ thermal interface solutions offer the flexibility you need for EV and hybrid battery pack design, and SILASTIC™ Liquid Silicone Rubber (LSR) was designed for integrated seals and electrical connectors and housings. From silicones to polyurethanes, these technologies extend battery life, improve safety, and lower energy consumption. Let's work together to redefine battery safety and performance.

VORATRON™ MA 8200 Adhesives Series

High-performing and reliable adhesives providing optimal bonding for diverse cell and battery designs, meeting demanding performance and quality needs. They’re designed for cell-to-module, cell-to-pack bonding, and cell-to-chassis solutions.

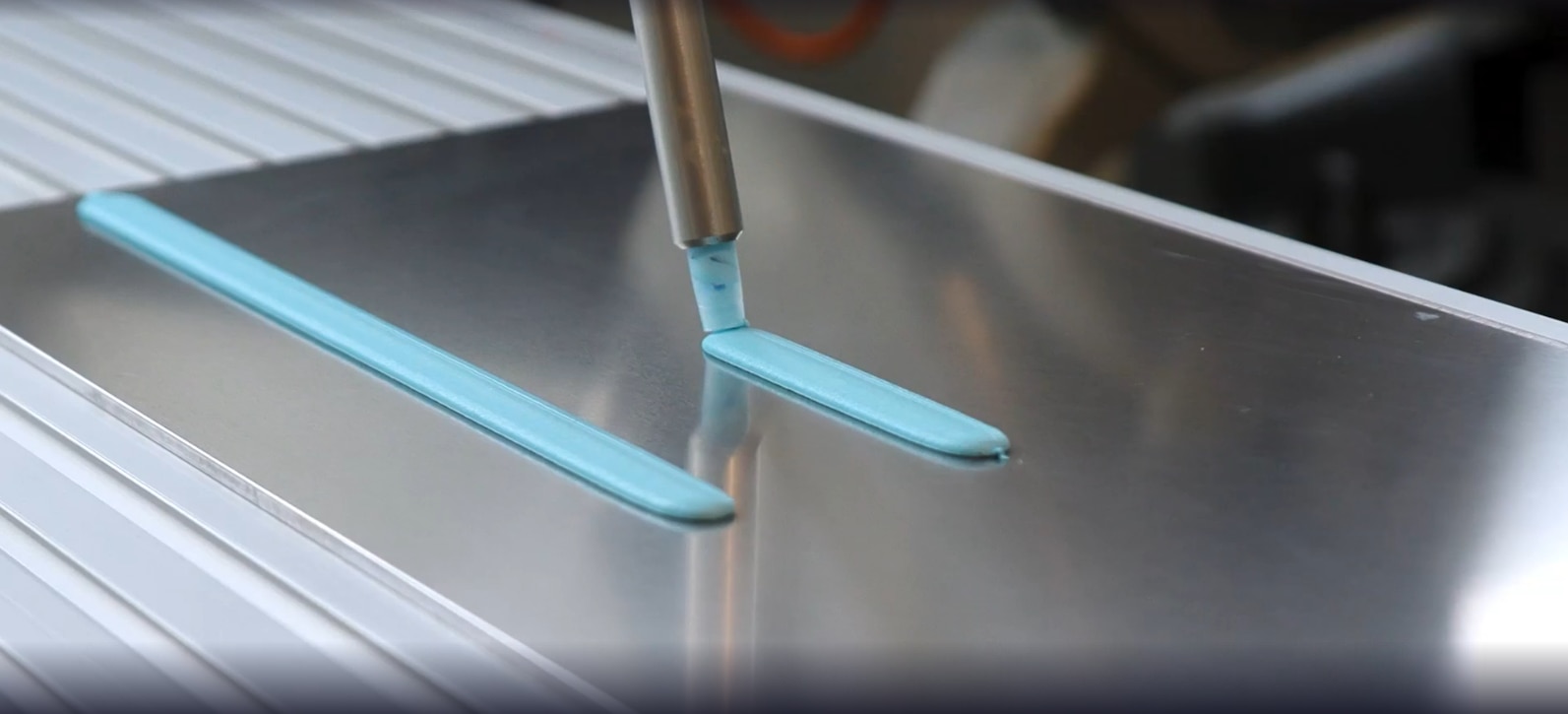

VORATRON™ GF 1000 Gap Filler Series

Optimize battery pack assembly with our two-part thermally conductive polyurethane gap fillers. Their very low squeeze force enables easy and safe handling, while their low density contributes to overall lightweighting.

VORATRON™ Potting Foam Series

Protect cells and batteries from thermal events with our polyurethane potting foams. These lightweight low-density solutions provide excellent thermal and mechanical isolation, fire resistance, high strength, and structural support.

DOWSIL™ 3-8259 RF Silicone Foam Kit

A two-part, room temperature silicone foam system designed to be dispensed and cured directly on parts to form an integrated compression gasket.

DOWSIL™ EA-3838 Fast Adhesive

RTV adhesive with full fixture time within 20 minutes, eliminates the need for ovens and primers in the assembly line, reduces cycle times from days to hours — or minutes, and bonds to a wide range of materials for fast in-line manufacturing.

DOWSIL™ TC-5533 Gap Filler

Two-part, 3.0 W/mK thermally conductive gap filler formulated to dissipate heat in electronics applications such as battery pack assembly. A low-density product, intended for high-volume applications.

Why choose Dow silicones for battery fire protection?

Passenger safety in electric vehicles is a top concern. Increasing safety standards are driving the need for advanced materials that mitigate battery thermal events like fire, explosion, or smoke.

Silicones offer key advantages for thermal runaway mitigation, including fire-resistant properties and ceramification capabilities, which create a thermally and electrically protective ceramic barrier when exposed to extreme heat. Silicones also offer thermal stability to support performance over a wide temperature range.

Design options for battery fire protection solutions

Dow silicones are available in different formats, delivering design flexibility across battery cell types and battery pack configurations. Our portfolio of battery fire protection solutions include:

- LSR coatings and encapsulants with rapid room temperature cure and ceramification in case of thermal events/high temperature arising for thermal, flame and particle blast protection.

- Silicone foam cures quickly, achieves low densities, and offers vibration reduction, electrical isolation and thermal/flame protection via ceramification.

- High-consistency rubbers (HCRs) offer rapid cure, superior electrical insulation and thermal/flame protection through ceramification.

Explore top silicone solutions for battery fire safety

DOWSIL™ EF-6555 Silicone Foam

Low density silicone foam designed for production into sheet foams for battery fire protection and battery insulation.

DOWSIL™ EA-3838 Fast Adhesive

Fast room temperature silicone cure adhesive designed for automotive electronics assembly, with excellent weathering and temperature stability.

DOWSIL™ 3-8259 RF Silicone Foam Kit

A two-part, room temperature silicone foam system designed to be dispensed and cured directly on parts to form an integrated compression gasket.

Looking for silicone solutions in electronic control unit assembly?

For enhanced reliability in electronic control unit (ECU) assembly and battery management systems, DOWSIL™ has been developed to protect modules from potential risks such as electrical failures and overheating.

Design options for electronic control assembly solutions

Dow’s portfolio includes protective solutions designed for electronic control assembly applications including:

- Coatings, gels, and encapsulants – These materials provide a robust barrier against moisture and contaminants, ensuring long-term performance in harsh environments.

- Electronic adhesives – Formulated for strong, durable bonds, these adhesives also offer excellent thermal management properties for densely packed control systems.

- Thermally conductive – Designed to maintain consistent thermal pathways, conductives help improve heat dissipation, supporting greater device reliability.

Featured DOWSIL™ silicones for EV batteries and control unit modules

DOWSIL™ 844 RTV Adhesive Sealant

One-part, fast cure, RTV adhesive useful in automated or manual dispensing systems for sealing of modules and multi-component assemblies; or for formed in place gasketing.

DOWSIL™ TC-4060 Thermal Gel

Rapid dispense thermally conductive gap filler formulated to dissipate heat in high throughput applications, like telecom power supplies, high frequency devices (5G), and electronic control units (ECU).

DOWSIL™ TC-6040 Thermal Conductive Encapsulant

This thermally conductive encapsulant is a heat cure product with good flowability. Formulated to encapsulate and dissipate heat on-board chargers, DC/DC converters for electric vehicles (EV), and other power electronics.

Thermal management and insulation materials for coolant hoses and busbars

Dow delivers reliable battery system performance with EPDM coolant hoses for thermal management and SILASTIC™ silicone rubber for high-voltage insulation. Our solutions help extend battery life, improve safety, and ensure efficiency in EVs, hybrids, and energy storage systems.

NORDEL™ EPDM: Materials for coolant hoses

Effective thermal management is critical to battery safety, longevity, and efficiency. Our premium EPDM coolant hoses deliver the reliability your battery cooling systems demand. Engineered for exceptional resistance to automotive fluids and extreme temperatures, our hoses perform flawlessly in demanding battery system conditions. From hybrid vehicles to industrial energy storage, trust our proven solutions to keep your batteries operating at optimal temperatures.

SILASTIC™: High Temperature Busbar and Hose Insulation Materials

SILASTIC™ High Consistency Silicone Rubber (HCR) delivers superior thermal and electrical insulation for high-voltage busbars and hoses in battery systems. Solutions are customized to meet specific application needs, with options available that comply with UL94 V0 flame resistance standards and ceramifiable formulations for comprehensive busbar protection before, during, and after thermal events.

Battery system product guides

Need help determining which products work best for your battery system? Explore these resources to learn more about Dow technologies and the features and benefits of our battery material solutions.

Material solutions for battery pack assembly

With a range of adhesives, gap fillers, potting systems and encapsulants, Dow can help battery manufacturers achieve the right level of protection required for diverse battery configurations.

Silicone material solutions for battery fire protection

Silicones are available in different formats and offer a unique set of properties that make them ideal for BFP applications. Explore how Dow silicones help make EV batteries safer and more reliable.

Questions about Dow Mobility products and capabilities? Get in touch with a representative.

Hear from Dow with our latest innovations and news as we accelerate towards a more resilient, low-carbon future.