Energy Conversion

Extending the life of your solar investment

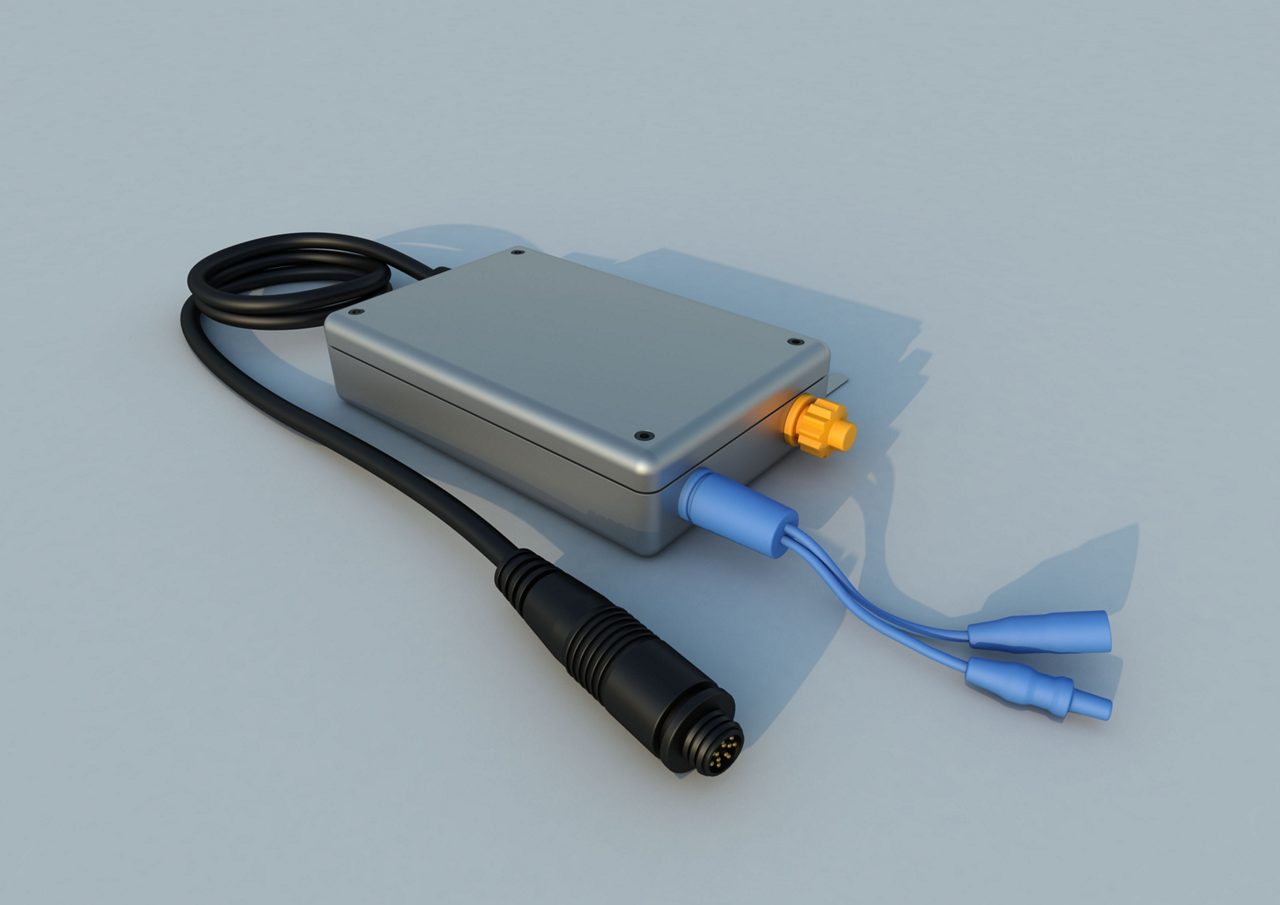

Solar energy must continue to push its cost per watt towards grid parity in order to occupy a larger share of the overall energy mix. Encapsulants, coatings, adhesives and thermal interface materials based on advanced Dow silicone technology help to protect and extend the service life of power optimizers, microinverters, and other energy conversion components that must operate under extreme heat and weather.

Why silicones?

Silicones are extremely durable materials that are able to retain their physical properties and outstanding performance under extreme environments. They are strong yet flexible, providing robust protection of the high-value electronics that drive power optimizers and microinverters.

Which silicones?

Silicone Encapsulants

In potting solutions, our silicone encapsulants contribute to lower PCB system assembly costs by eliminating the pre-heating step required for polyurethanes. For even faster filling, we offer simple room-temperature cure materials with the option of reducing cure time to 20 minutes at temperatures of 50°F.

Solventless and Low VOC Conformal Coatings

In the field, our solventless and low VOC conformal coatings solutions protect high value electronics from the changes in season, harsh sun and other environmental assaults that impose repetitive thermal cycling and mechanical stress. Unlike acrylic options, our silicones process easily without residual moisture that extends cycle times and compromises coating quality.

Adhesives and Sealants

For unprimed adhesion to a variety of substrates, our silicone adhesives and sealants offer simple room temperature cure with the option to accelerate cure time. They hold up to repeated exposure to strong electrical fields, extremes in humidity and temperatures ranging from -45° to 200°C.

Thermally Conducted Gap Filler

To moderate internal heat, we offer a growing portfolio of thermally conductive adhesives, encapsulants and dispensable thermal pads designed to withstand increases in heat resulting from electronics that operate at higher power densities and frequencies.

Dow Electronics Protection & Assembly Academy-Lab Series: Temperature Ranges

This video describes uses and properties of silicones at high and low temperature extremes and comparison with organic products and how glass transition temperature impacts performance ranges is discussed.

Energy conversion resources

Low stress silicone encapsulant enables distributed power generation

DOWSIL™ EA-4700 CV Adhesive: Two-part room temperature, fast-curing silicone adhesive

Product Selection Guide: Optimized precision, power and protection for industrial electronics applications

We are committed to connecting you with experts and resources to tackle any challenge.