Sustainable MobilityScience™

How do we drive circularity and low-carbon mobility?

Learn how Dow MobilityScience™ enables sustainable mobility solutions to enable circularity and improve energy efficiency for a low-carbon future.

Sustainable solutions throughout the vehicle lifecycle

To drive sustainability that supports resilient, low-carbon mobility, we believe every automotive company, vehicle brand, and individual has a unique responsibility. At Dow, that means accelerating our commitment to sustainability: climate protection, engineering safer materials, and enabling circularity.

To emerge as winners in the race to sustainable, lower-carbon mobility, OEMs are acting across the entire lifecycle of a vehicle. Materials science and collaboration are powerful assets in navigating this transition. That’s why MobilityScience™ was created – to provide a single point of expertise in materials science that covers the full spectrum of the sustainable mobility challenge while helping to enable the next generation of electric vehicles (EV) and autonomous vehicles (AV).

Explore each lifecycle phase using the tabs:

Sustainable by design

Our design principle is to use the least materials possible to achieve the highest performance possible. Collaborating with customers early in the design phase enables Dow MobilityScience™ experts to recommend and create tailored, lab-tested material solutions that unlock efficiencies in each phase of the vehicle’s life.

Optimal chemistry and material specifications – thoroughly tested in our labs – deliver a wide range of performance benefits to OEMs seeking to maximize sustainability in their designs.

Circular polyurethanes

Polyurethane-based solutions significantly improve the durability and energy efficiency of automobiles, trucks, aircraft and ships. Our MobilityScience™ team is committed to innovating new technologies and products for making this material even more valuable.

In 2021, Dow announced a mass-balance approach to the production of new polyurethane solutions based on a circular feedstock sourced from a waste product of the mobility sector that replaces virgin fossil-fuel-based feedstock. Our new SPECFLEX™ C and VORANOL™ C product ranges are initially being offered to the mobility sector in collaboration with leading automotive suppliers Adient and Autoneum.

The urgency of smaller carbon footprints and more efficient operations

Due to its significant greenhouse gas (GHG) impact, the global manufacturing sector bears a unique responsibility for pioneering progress in environmental stewardship. That’s why Dow helps customers reach their Scope 1 objectives with solutions that help to enable greater production efficiency and the use of fewer materials. We also help them achieve Scope 3 objectives using material options with a lower carbon footprint. Dow has doubled down on our own sustainability commitments, making significant investments in renewable energy to achieve our own Scope 2 goals. We understand the urgency and importance of this work to all our mobility sector partners and customers.

Every day, Dow’s MobilityScience™ team is helping customers reduce their carbon-intensive processes and enable the carbon-saving power of remanufacturing through optimal design and material selection.

Your partner in sustainability

Every day, Dow’s MobilityScience™ team helps customers reduce their carbon-intensive processes and enable the carbon-saving power of remanufacturing through optimal design and material selection.

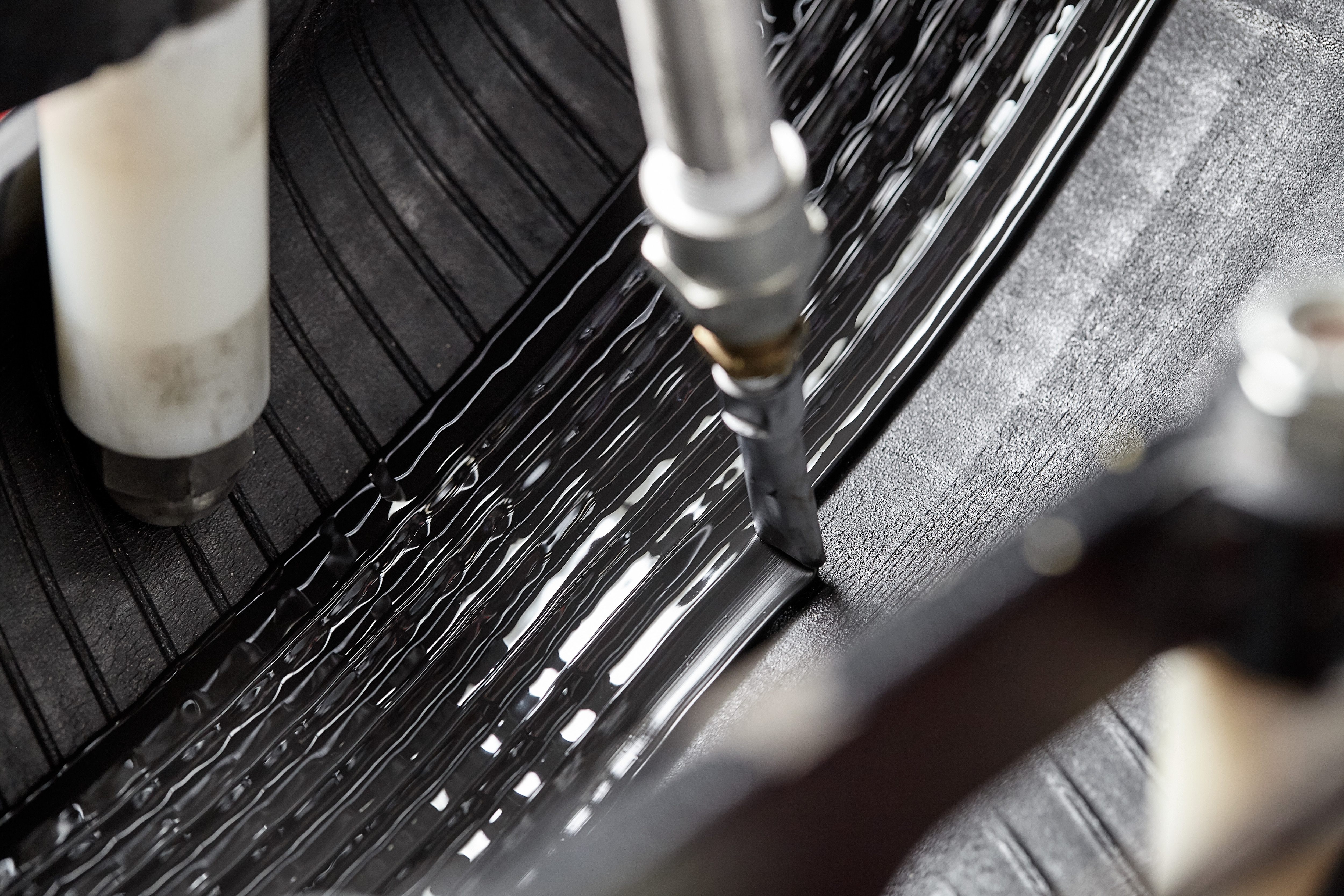

Sustainable manufacturing with production efficiency

How does 90% less energy use during combustion and electric vehicle assembly sound? Advanced adhesives provide process savings through rapid cure at lower temperatures.

Enhanced process efficiency for electrical connectors

What about reducing the temperature needed for curing electrical connector seals? Recent materials innovations make it possible while also helping to improve safety, increase design freedom and enhance process efficiency.

Consistent sustainable performance

Everyday vehicle use is far and away the most carbon-intensive aspect of the mobility lifecycle, which is why OEMs are fundamentally shifting their focus to alternative solutions like electric or hydrogen mobility. Whether you’re prioritizing electric or improving fuel efficiency, Dow helps deliver everyday sustainability performance to OEMs for vehicles in countless ways.

What are your biggest use-phase sustainability challenges?

Explore the materials unlocking new levels of efficiency during the tens of millions of vehicle trips taken every single day. Together, we can reduce emissions associated with the use phase - by transitioning to EV, implementing better emission control technology and more.

Revolutionizing lighting

Drivers demand brighter, more energy-efficient and longer-lasting lighting systems. Our moldable optical innovations reduce the weight of auto interior and exterior LED lighting components by replacing glass or thermoplastics.

Efficiency with insulation

Lightweight insulation materials reduce energy through more efficient vehicle heating and air conditioning and promote circularity through the innovative use of feedstocks sourced from automotive industry waste.

Battery systems for better EVs

Low-density, high-performance thermally conductive gap fillers help extend the life and performance of EVs by dissipating heat from EV battery and control unit modules. Additionally, Dow’s structural foam enables new battery pack designs that save weight and cost without compromising safety.

Sustainable automotive bodies and panels

Did you know that replacing metal with thermoplastic polyolefins in panels reduces weight by 25% (and manufacturing costs by up to 8%), helping to reduce emissions?

The circular journey to a sustainable future

The mobility sector accounts for around 20% of global greenhouse gas emissions. We urgently need to manage materials wisely and efficiently throughout our supply chains and production cycles.

At Dow, we’re engineering materials solutions for sustainable disassembly and exploring new technologies to create parts that can be reused, repaired, or recycled.

The way forward isn’t a straight path; it’s circular. Our MobilityScience™ team is committed to working alongside customers and partners to unlock the full potential of materials science for a circular economy approach and navigate increasingly stringent government regulations around emissions and waste management.

Recycling and reuse of silicone material

Dow has been reprocessing and recycling actives since 2005, converting siloxane-rich byproducts back to a fluid state. The next step toward post-industrial and post-consumer recycling of silicones is the development of thermal treatment technology, where evaluation testing is currently ongoing.

Dow has also initiated the exploration of mechanical silicone recycling with the goal of creating a final material with an equal or lower carbon footprint and lower capital intensity than virgin siloxane production. This has become a reality with the award-winning SILASTIC™ SST-2650 Self Sealing Silicone tire solutions created in partnership with Bridgestone.

The power of partnerships in the circular economy

Dow & Gruppo Fiori pioneer polyurethane recycling breakthrough

Together, the companies created a novel process to recover polyurethane foam from end-of-life vehicles without disassembly and convert it into new recycled materials. Building on their 2024 MoU, this breakthrough advances circularity and helps OEMs meet regulatory goals.

Charting a new path towards circularity with Gruppo Fiori

Under a new MoU, Dow and Gruppo Fiori will develop new strategies for recycling end-of-life vehicle materials and parts. Combining expertise in polymers, polyurethanes, and materials sorting, the collaboration supports a circular economy for automotive.

Driving a Low-Carbon Future in Mobility

Dow understands the importance of partnering across the value chain to address sustainability challenges and invest in the right solutions to meet regulations. Collaboration across industries, government and communities is key to advancing a low-carbon, circular economy.

Questions about Dow Mobility products and capability? Get in touch with a representative.

Hear from Dow with our latest innovations and news as we accelerate towards a more resilient, low-carbon future.