Materials Ecosystem

Unlocking the Value of Waste

Dow’s approach for a better way to make, use and reuse plastics.

What is the materials ecosystem?

The materials ecosystem addresses our plastics challenges today: consumers’ the evolving concern for their environmental footprint and the surge in demand for more sustainable products and packaging.

Interconnected, this circular system helps reduce plastic waste and creates a new value chain for scientific innovation, jobs and collaborations.

The ecosystem is a transformation in plastic waste handling. Countries transform at different paces depending on their unique circumstances. Yet, there is an opportunity to leap-frog by learning collaboratively, creating infrastructure and policies that move us forward in the same direction.

Explore the elements of the materials ecosystem

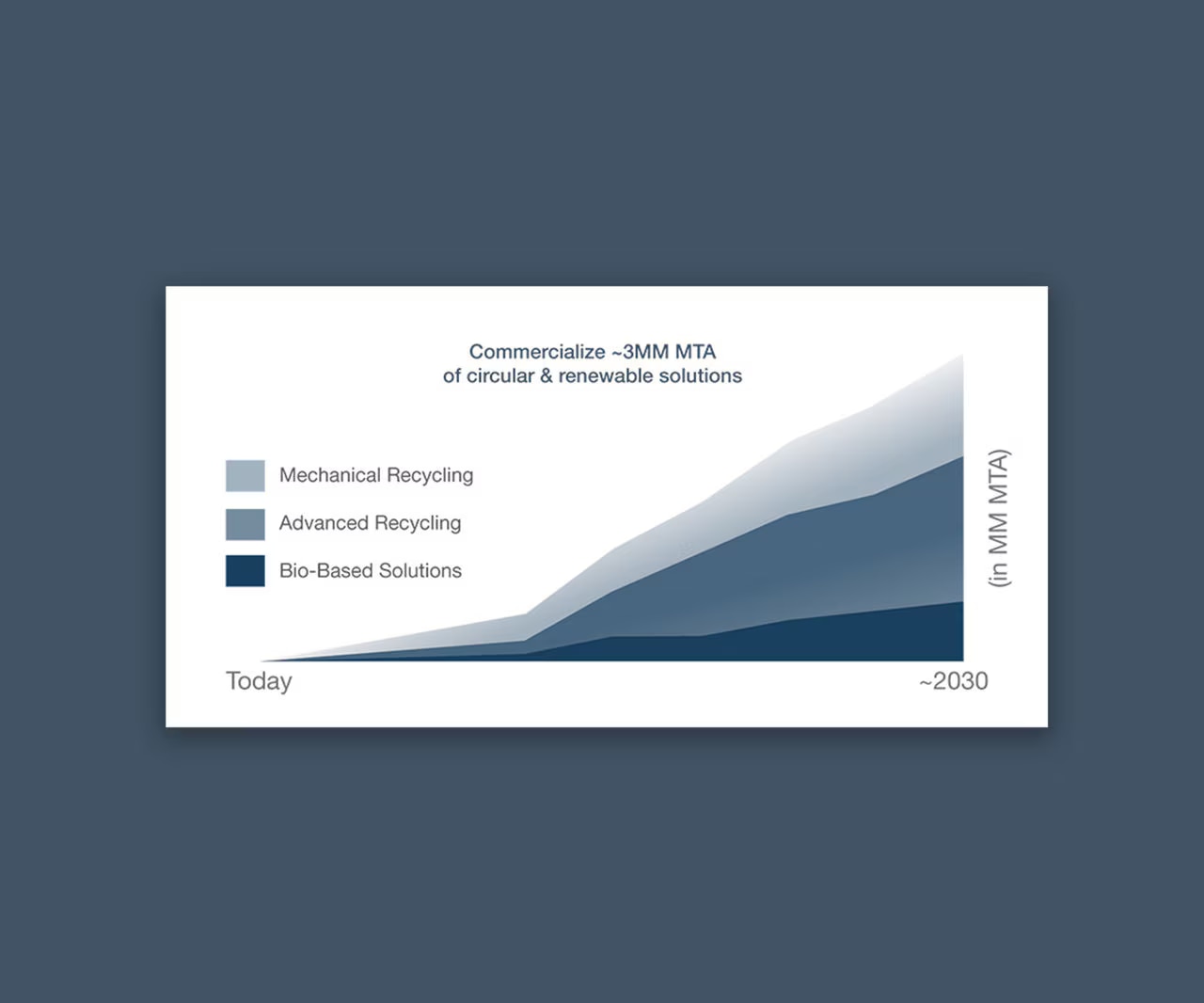

Mechanical recycling is a process, by which plastic waste is turned into new products without the structure being significantly altered. Plastic manufacturers can use this material in applications with less performance needs, such as trash bags, rigid plastic containers and building materials.

Featured collaborations

To enable broader use of recycled plastic, Dow is investing in advanced recycling. Advanced recycling offers massive, untapped market potential and the ability to bring circularity to previously incompatible areas such as food-grade and medical-grade packaging by using the same material for reuse.

Featured collaborations

To produce new plastic materials that are more sustainable — and reduce the use of fossil feedstocks and the carbon footprint associated with them — it will take a combination of feedstocks produced from recycled plastic waste and bio-circular materials. Dow focuses on non-edible renewable resources.

Featured collaborations

There is a gap between downstream demand for circular plastics and available supply. The local players in waste management, recycling, design and manufacturing are essential to waste reaching its full potential through local recycling options, infrastructure, education and incentives.

Featured collaborations

Design is indispensable to supporting markets in transforming materials use for less environmental impact. Brand owners and manufacturers must consider tradeoffs between cost and performance while ensuring that product integrity remains intact. Learn how we can meet targets to enable recyclability.

Featured collaborations

Improving recycling requires understanding what drives behavior and creating conditions that support the recycling behavior we seek. Dow’s environmental nonprofit partners — including the Alliance To End Plastic Waste, The Recycling Partnership, Delterra and others — are demonstrating that behavior change is possible.

Featured collaborations

Dow is investing approximately $1 billion annually to drive growth & decarbonization of our manufacturing assets by replacing end-of-life, carbon-intensive assets with more carbon-efficient and carbon abatement technologies, such as circular hydrogen, nuclear and carbon capture and storage.

Featured collaborations

Policymakers, investors, and non-profit organizations are the global tailwinds enabling circular supply chains.

Featured collaborations

The Materials Ecosystem

How connected systems and people are helping plastic waste reach its full potential.

Unlocking the value of waste

We’re talking about the materials ecosystem and Dow’s approach for a better way to make, use and reuse plastics. Learn how a materials ecosystem is developing around plastic and renewable waste to deliver its total value.

Partnerships and collaborations

Explore our sustainable solutions

Sustainable Packaging

Dow offers a broad technology portfolio along with application expertise to help companies design packaging that delivers on sustainability and performance.

Sustainable Personal Care Solutions

Safe personal care solutions for people and the planet.

Accelerating a Sustainable Future in Construction Chemicals

Leading the transition to a more sustainable and resilient construction industry.

Home Care Sustainability

Home care solutions for a better world.

Sustainable MobilityScience™

Sustainable solutions throughout the vehicle lifecycle.

A Sustainable Future with Polyurethanes

At Dow, we’re accelerating our sustainability journey towards a low carbon and circular future.

Materials ecosystem resources

We're working across industries to deliver solutions that help our customers meet their sustainability targets and goals.

A global plastic pollution agreement can incentivize circularity and enhance waste management infrastructure.

Haley Lowry, Director of Sustainability, talks waste transformation with Dow collaborators at the Fast Company Innovation festival.

Read the full Dow progress report to learn how we're accelerating our roadmap to Transform the Waste.

Join the ecosystem

Get in touch to collaborate with us.